The rise of smart surfaces with hidden touch controls has revolutionized user interfaces across consumer electronics, automotive dashboards, and even architectural elements. These sleek, minimalist designs eliminate physical buttons in favor of capacitive or pressure-sensitive zones beneath continuous materials like glass, wood, or composite panels. However, as manufacturers push the boundaries of seamless interaction, unintended touch activation—commonly referred to as "false triggers" or "ghost touches"—has emerged as a critical pain point impacting user experience and product reliability.

Understanding the root causes of false touches requires examining the intersection of hardware sensitivity, software interpretation, and real-world usage patterns. Modern touch-sensitive surfaces rely on complex arrays of electrodes or strain gauges that detect minute changes in capacitance or pressure. While this enables futuristic designs, environmental factors like moisture, temperature fluctuations, or electromagnetic interference can generate noise that mimics genuine touch signals. A coffee ring left on a smart table might register as a finger tap, while a passenger leaning against a car door with touch-sensitive controls could accidentally activate window functions.

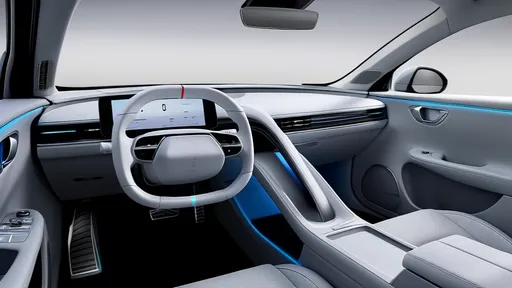

Software algorithms play an equally crucial role in this delicate dance. Overly aggressive touch detection thresholds may interpret environmental noise as intentional input, while excessively conservative settings create dead zones that frustrate users. The challenge intensifies with multi-touch surfaces where palm rejection must distinguish between deliberate gestures and incidental contact. Some high-profile product recalls have stemmed from systems misinterpreting raindrops as swipe commands or failing to ignore sleeves brushing against touch-enabled steering wheels.

Material science introduces another layer of complexity. The dielectric properties of overlay materials significantly impact capacitive touch performance. While glass provides excellent signal clarity, increasingly popular textured surfaces—matte finishes, woven composites, or natural materials like stone veneers—can scatter electrical fields unpredictably. Automotive interiors exemplify this challenge, where designers balance aesthetic appeal against reliable touch performance across materials ranging from leather to recycled plastics.

Industry responses to false activation problems have spawned innovative engineering solutions. Advanced signal processing techniques now employ machine learning to analyze touch patterns over time, distinguishing between transient environmental artifacts and deliberate human interaction. Some systems incorporate secondary sensors—such as proximity detectors or cameras—to provide contextual awareness about whether a user is actually attempting to engage with the interface. Haptic feedback has also emerged as a critical failsafe, providing tangible confirmation that prevents users from repeating commands they didn't realize were registered.

The evolution of touch surface standards reveals how seriously the industry takes this issue. Where early implementations relied on manufacturer-specific protocols, cross-industry working groups have developed testing methodologies that simulate real-world stress conditions. These include standardized contamination tests (oils, lotions, moisture), extreme temperature cycles, and electromagnetic compatibility trials. Compliance with these benchmarks has become a key differentiator for premium products, particularly in automotive and medical applications where false activations could have safety implications.

Consumer education forms an often-overlooked component of reducing unintended interactions. Many frustration cases stem from users not understanding a surface's active zones or the required touch pressure. Thoughtful onboarding experiences—from subtle glyphs that appear on dormant surfaces to tutorial modes in companion apps—can dramatically improve first-use accuracy. Some designers are even experimenting with dynamic active areas that adapt based on usage context, shrinking touch targets when the system detects high likelihood of accidental contact (like in a moving vehicle) and expanding them during deliberate interaction sessions.

Looking ahead, the next generation of smart surfaces may render the false touch debate obsolete through fundamentally different sensing paradigms. Millimeter-wave radar embedded in surfaces can detect finger proximity before physical contact occurs, while self-capacitance systems measure the entire body's electrical interaction rather than localized contact points. These technologies promise interfaces that understand user intent rather than just measuring physical inputs—potentially creating surfaces that are simultaneously more responsive and less prone to errors.

The quest to perfect hidden touch interfaces reflects a broader tension in technological progress—the balance between aesthetic minimalism and functional reliability. As the industry matures, solutions are emerging not from choosing between these priorities, but from innovations that satisfy both. The smart surfaces of tomorrow won't just be beautiful slabs of unbroken materials; they'll be context-aware systems that understand the difference between a coffee spill and a conscious command, between an errant elbow and a deliberate swipe. That's when the true potential of seamless interaction will finally be realized.

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025