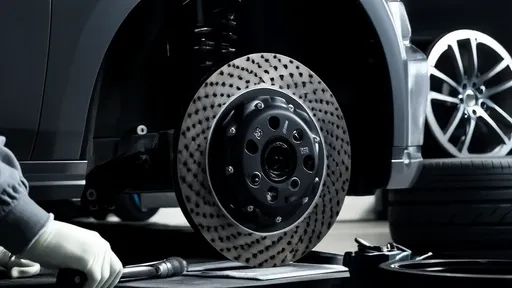

The world of high-performance tires is a fascinating intersection of chemistry, physics, and engineering. When it comes to tires designed to handle speeds exceeding 200 km/h, the rubber compound becomes a critical factor that separates ordinary tires from those capable of delivering exceptional grip, durability, and heat resistance. Unlike standard tires, which prioritize longevity and fuel efficiency, high-speed rubber formulations must balance multiple competing demands to perform flawlessly under extreme conditions.

At the heart of any high-performance tire is the rubber compound itself. The base material is typically a blend of natural and synthetic rubber, but the magic lies in the additives and their precise ratios. Carbon black, silica, and various polymers are carefully mixed to create a compound that remains stable at high temperatures while providing the necessary traction. The tread compound for 200 km/h+ tires is often softer than that of all-season tires, allowing for better grip but at the cost of reduced tread life. This trade-off is necessary to ensure that the tire maintains contact with the road surface even under intense centrifugal forces.

Heat management is one of the biggest challenges in designing rubber for ultra-high-speed tires. As speed increases, so does friction, and with it, tire temperature. If the rubber cannot dissipate heat efficiently, it can lead to blistering, tread separation, or even catastrophic failure. To combat this, tire engineers incorporate specialized heat-resistant polymers and fillers that enhance thermal conductivity. Silica, for instance, not only improves wet grip but also aids in heat dissipation. Additionally, the compound may include oils and resins that help maintain flexibility at elevated temperatures, preventing the rubber from becoming brittle under stress.

The tread pattern and tire construction play supporting roles, but without the right rubber formulation, even the most advanced designs would fall short. High-speed tires often feature a lower aspect ratio and stiffer sidewalls to improve stability, but the rubber must complement these structural elements. The compound must be responsive enough to transmit steering inputs precisely while remaining compliant enough to absorb minor road imperfections. This delicate balance is achieved through meticulous testing and iterative refinement of the rubber blend.

Another critical consideration is how the rubber behaves across a range of temperatures. Unlike racing slicks, which are designed for optimal performance within a narrow temperature window, road-legal high-performance tires must function in varying climates. The compound must provide sufficient grip in cold conditions without overheating during prolonged high-speed runs. This is where multi-zone tread compounds come into play, with different rubber formulations used in specific areas of the tread to optimize performance across diverse driving scenarios.

Durability remains a concern, even in tires designed for extreme speeds. While grip and heat resistance are priorities, the rubber cannot degrade too quickly under normal driving conditions. Advanced polymers and anti-oxidants are added to the mix to slow down wear and resist environmental factors like UV exposure and ozone. Some manufacturers even use nanotechnology to reinforce the rubber at a molecular level, enhancing both strength and elasticity.

The development process for these rubber compounds is as much an art as it is a science. Tire engineers spend countless hours on dyno testing, track evaluations, and real-world simulations to fine-tune the formulation. Small adjustments in the percentage of a single additive can have a dramatic impact on performance, making the process highly iterative. Computational modeling has accelerated development in recent years, but there’s no substitute for physical testing when it comes to validating a new rubber blend.

Looking ahead, the quest for better high-speed rubber compounds continues. With electric vehicles pushing the boundaries of acceleration and top speed, tire manufacturers are exploring new materials and technologies. Graphene-infused rubber, for example, shows promise in delivering superior heat dissipation and mechanical properties. As automotive performance evolves, so too must the humble tire—and it all starts with the rubber.

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025