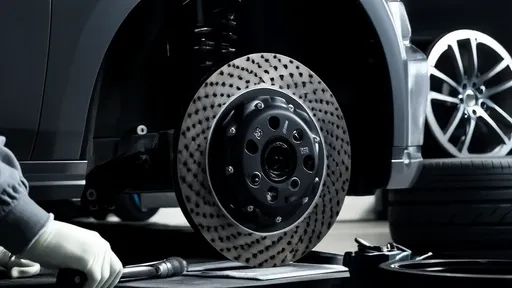

The automotive world has long been fascinated by the allure of carbon-ceramic brakes. Originally developed for high-performance racing applications, these braking systems have gradually made their way into premium road cars, promising unparalleled stopping power, reduced weight, and exceptional durability. Yet, despite their advantages, the widespread adoption of carbon-ceramic brakes in street vehicles remains hampered by one critical factor: cost.

Carbon-ceramic brakes, often referred to as carbon-ceramic matrix composites (CCMCs), are a marvel of modern engineering. Unlike traditional cast iron or steel brakes, they are constructed from carbon fibers embedded in a silicon carbide matrix. This unique composition grants them the ability to withstand extreme temperatures—up to 1,800 degrees Fahrenheit—without fading, a common issue with conventional brakes during aggressive driving. Additionally, they are significantly lighter, reducing unsprung weight and improving handling dynamics.

From the racetrack to the showroom, the journey of carbon-ceramic brakes has been anything but straightforward. In motorsports, where performance is paramount and budgets are often secondary, these brakes have become a staple. Formula 1 cars, Le Mans prototypes, and even top-tier GT racing machines rely on them for consistent, fade-free braking under the most demanding conditions. Automakers, eager to translate this racing pedigree into their flagship road cars, began offering carbon-ceramic brakes as optional or standard equipment on high-end models.

However, the transition from track to street has exposed a glaring disparity. While racing teams can justify the exorbitant cost of carbon-ceramic brakes due to their competitive edge, everyday drivers face a much harder sell. A set of carbon-ceramic brakes for a premium sports car can easily exceed $15,000—sometimes even reaching $20,000 or more. For context, this is often more than the total cost of a well-equipped economy car. The question then becomes: Are these brakes truly worth the premium for the average driver?

The manufacturing process of carbon-ceramic brakes is a key driver of their high cost. Producing these components is a labor-intensive and time-consuming endeavor. The carbon fibers must be carefully woven into a preform, which is then infiltrated with liquid silicon under high pressure and temperature. The resulting material is then machined to precise tolerances, a process that requires specialized equipment and expertise. Each step adds to the final price tag, making mass production economically unfeasible at this stage.

Another factor contributing to the cost is the limited number of suppliers capable of producing high-quality carbon-ceramic brakes. Companies like Brembo, Carbon Industrie, and Surface Transforms dominate the market, but their production capacity is constrained by the complexity of the manufacturing process. This scarcity allows them to command premium prices, particularly for automotive OEMs looking to equip their halo models with the latest braking technology.

Despite their advantages, carbon-ceramic brakes are not without drawbacks, especially in everyday driving scenarios. For one, they require significant heat to achieve optimal performance—something that is rarely generated during normal commuting. In cold or wet conditions, their initial bite can be less responsive than traditional brakes, a characteristic that has drawn criticism from some drivers. Moreover, while they are touted as "lifetime" components, their replacement cost—should they ever wear out or sustain damage—is prohibitively expensive.

The aftermarket dilemma further complicates the picture. Unlike conventional brakes, which can be easily serviced or replaced by independent mechanics, carbon-ceramic systems often require specialized tools and knowledge. This forces owners to rely on dealerships or certified service centers, where labor rates are significantly higher. Even routine maintenance, such as pad changes, becomes a costly affair, deterring many potential buyers from opting for these brakes in the first place.

Automakers are acutely aware of these challenges and have been exploring ways to mitigate the cost barrier. Some have introduced hybrid systems that pair carbon-ceramic rotors with traditional brake pads, offering a middle ground between performance and affordability. Others are investing in research to streamline the manufacturing process, hoping to achieve economies of scale that could eventually bring prices down. However, breakthroughs in this area have been slow, leaving carbon-ceramic brakes firmly in the realm of high-end exclusivity.

For now, carbon-ceramic brakes remain a symbol of automotive prestige—a feature reserved for those willing to pay a premium for cutting-edge technology. While they undoubtedly offer tangible benefits in performance-oriented settings, their practicality for everyday use is still up for debate. Until the cost equation shifts dramatically, these high-tech braking systems are likely to remain a niche offering, tantalizingly out of reach for the majority of drivers.

The road ahead for carbon-ceramic brakes is fraught with challenges, but also opportunities. As material science advances and production techniques evolve, there is hope that these systems could become more accessible. Until then, they will continue to occupy a paradoxical space in the automotive world—simultaneously celebrated for their performance and criticized for their prohibitive cost.

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025

By /Jun 14, 2025